Services

Hot Heading | Grinding | Heat Treating | Shot Blasting | Machining | Plating | Threading

We shape our services to provide our customers with the highest quality products, with the fastest lead times, and exemplary customer service. As your one-stop-shop for all of your fastening needs, we not only supply you with the tools you need but we can also help you discover exactly what you need and then we can custom manufacture it.

Thanks to our suppliers, who are right down the road, we are able to accommodate any order very quickly, no matter how large or small.

We also offer supplementary services such as research and development, metallurgical consulting, and product testing. We understand how important it is for your application to work right the first time and every time. That is why we are always improving our processes and services so that you don't have to do the hard work.

Hot Heading

Hot Heading

Master Bolt hot forges heads onto bolts using Ajax and National Upsetter machines. Calculations are made to determine the amount of material needed to forge the head onto the bolt before the raw stock is sheared into blanks. Once the material has been sheared, an operator will set the machine up with the proper tooling to form the head. First, the blank will be placed into an induction machine to heat the end of the bar to a specific temperature for it to be formed. Then the Upsetter compresses the heated steel to form the head on the bolt.

Master Bolt has the capability to form ½” up to 2” diameter fasteners, bolts, from 2” to 100” in length. Common head styles include square, hex, carriage, dome, round, countersunk and spikes. There are many other head styles available upon customer demand. We also offer your custom product with your company’s name or logo forged into the head.

Grinding

Grinding

Master Bolt offers Centerless grinding and surface grinding.

Centerless grinding is similar to centered grinding with the exception that there is no spindle. Surface grinding generally removes a small amount of material, creating a mirror-like finish to obtain tight tolerances.

Heat Treating

Heat Treating

Master Bolt works closely with a local heat treat facility who is ISO-9001 certified. Heat treating is a group of industrial and metalworking processes used to alter the physical, and sometimes chemical, properties of a material. Our customers typically require heat treating to grade 5 or grade 8, bolt straightening and annealing. A few other processes our heat treater offers but is not limited to is Case Hardening, Carburizing, Carbonitriding, Neutral Hardening, Normalizing, Induction Hardening, Stress Relieving and much more. If required by our customer, we will supply a certification. If other testing is required, we will send the product to a certified outsourced vendor for testing, who will provide a certification of results.

Shot Blasting

Shot Blasting

Master Bolt Shotblast’s material to remove any surface defects on our parts. Shot Blasting is the process of stripping a metal surface with a constant, high-speed stream of steel particles.

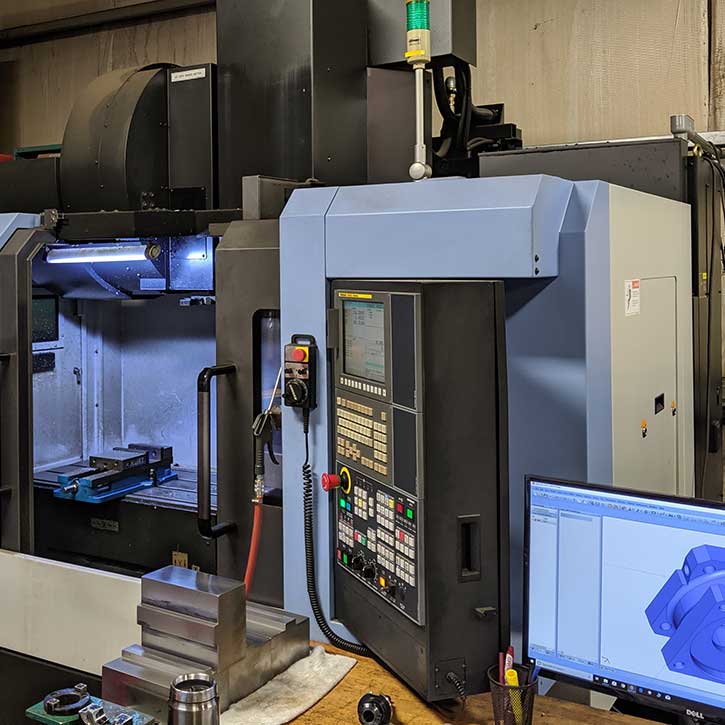

Machining

Machining

Master Bolt offers various types of machining processes giving us the capability to tailor to our customers’ demands. Multiple state of the art CNC Lathes and Mills with programmers on-site to provide our customers with their desired parts in a timely manner. Other machines include Manual Mills, Lathes, Drilling centers, various types of saws, metal shearing machines, etc.

Plating

Plating

Master Bolt works with a local plating company that offers but is not limited to Galvanizing, Zinc-Yellow, Zinc-Clear, Trivalent, Electro Polish and much more. Plating is a manufacturing process in which a thin layer of metal coats a substrate. This can be achieved through electroplating and by electroless plating. If required by our customer, we will provide a certification of results.

Threading

Threading

Master Bolts threading capabilities are cut threads and rolled threads ranging in various sizes.

Roll threading implies introducing a hardened steel die between the diameters of the finished thread. The dies penetrate the blank space, leading the newly formed thread roots outwards to create the crests. Master Bolt has the capability to Roll thread ½” to 1-1/4” in diameter.

Cut threading entails removing the material from a round bar of steel to form the threads. Master Bolt has the capability to cut thread from ½” to 3” diameter.

Our Products

Every Product We Manufacture is Completely Customizable!

CONTACT MASTER BOLT

Custom Bolt Manufacturer in Elyria, OH

7:00 AM - 5:00 PM

(440) 323-5529

For more information about our services, or if you'd like to review your company's hardware needs,

contact us at (440) 323-5529 or toll-free at (888) 905-2658.

We look forward to providing you with the best custom made industrial hardware in the U.S.